In terms of enhancing the excavator's performance, picking the right parts is essential. Excavators hold a key role in construction, mining, and multiple other industries, and their productivity directly affects project schedules and costs. If you're replacing worn components or upgrading for enhanced functionality, recognizing the value of quality excavator parts can make all the difference.

Spending in high-grade parts not just ensures the durability of your machinery but also optimizes its performance in the field. With so many options available, working through the options can be challenging. It is crucial to research thoroughly and choose parts that are fit with your particular model and meet the demands of the job. In this article, we will explore key considerations for acquiring excavator parts that will get the most out of your machinery.

Grasping Excavator Parts

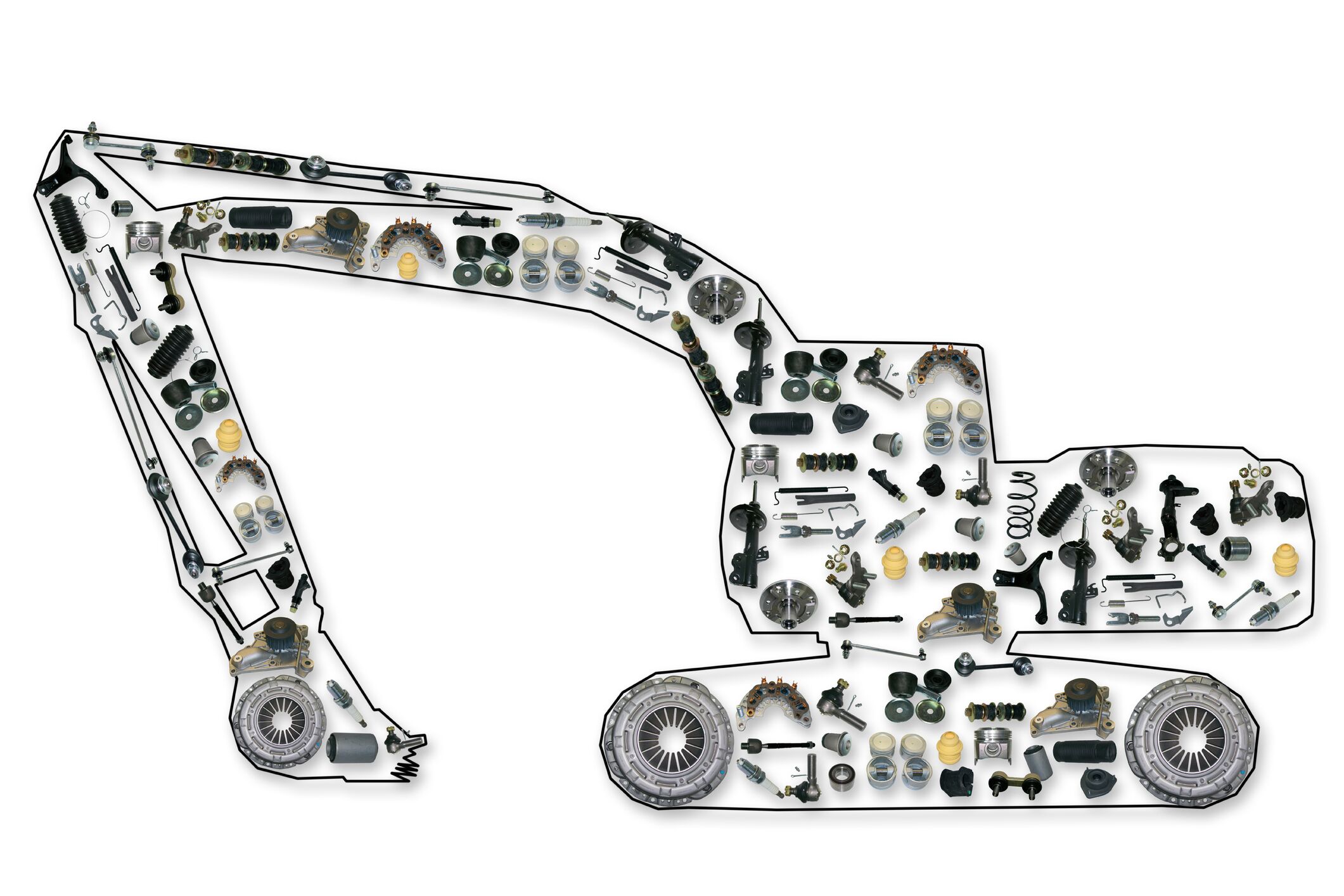

Excavator machines are sophisticated equipment made up of various parts that work together to execute heavy jobs. Knowing these components is key for anyone wishing to buy excavator parts, as knowing what each part does can help you make wise choices. Important parts include the boom, linkage, scoop, and chassis, each contributing to the overall performance and capability of the machine.

The boom is the long hydraulically operated component that reaches out from the core structure of the excavator. It is important in reaching profound or elevated areas, allowing the machine to dig, lift, and move items efficiently. The link connects the boom to the scoop and is responsible for the digging process. Ensuring that the boom and link are in optimal shape is vital for peak functionality, as any damage can considerably affect the excavator's performance.

The scoop, often deemed the most important part, is where the actual excavation happens. Buckets come in various designs and dimensions, tailored to different types of materials and excavation tasks. Whether you need a standard scoop, a slim bucket for trenches, or a heavy rock bucket, selecting the appropriate one can improve your excavator's efficiency and effectiveness. Grasping the function of the bucket and other parts can help you select the most suitable components for your particular needs.

Selecting High-Quality Replacement Components

In the realm of ensuring the performance and lifespan of your equipment, choosing top-notch replacement parts is vital. The performance of your excavator greatly depends on the quality of the parts you choose. Using subpar components can cause frequent malfunctions, decreased productivity, and ultimately increased repair costs. Always select OEM components or reputable manufacturers known for their quality.

Additionally, it is crucial to confirm that the components you are acquiring are appropriate with your particular machine type. Specific information can usually be located in the user manual or by getting advice from professionals. Mismatched parts can lead to improper function and can even ruin your excavator over the long term. Conducting research and ensuring suitability will save you time and expenditures in the long run.

In conclusion, think about the warranty and service available with the parts you buy. A robust warranty reflects the manufacturer's assurance in their parts and can provide you with peace of mind. If you face issues after the purchase, responsive customer support can be invaluable in addressing issues quickly, allowing you to get your equipment back to working order without additional hold-ups.

Servicing Suggestions for Optimal Performance

Regular maintenance is crucial for keeping your excavator parts in top condition. Start by implementing a consistent inspection schedule to check for wear and tear on critical components such as the hydraulics, tracks, and blades. Address any problems promptly to avert further deterioration and maintain optimal performance. Cleaning the machine regularly also assists to eliminate dirt and debris that can cause wear over a period.

Another important facet of maintenance is ensuring that all fluid levels are monitored and maintained. Hydraulic fluids, engine oil, and coolant should be checked frequently and replaced as necessary to maintain smooth operation. Using cummins parts designed for your specific model will enhance efficiency and longevity. Don’t forget to replace filters as recommended by the maker to keep the system clean and functioning efficiently.

Finally, purchasing genuine excavator parts when replacements are necessary can significantly influence performance. While aftermarket parts might seem cost-effective, they often lack the precision and reliability of OEM parts. Consistently refer to your excavator’s manual for specifications and guidelines to ensure you are using the best components for your machine. This will assist you achieve maximum productivity and prolong the lifespan of your excavator.